Extraordinary furniture fronts with SIBU DESIGN panels

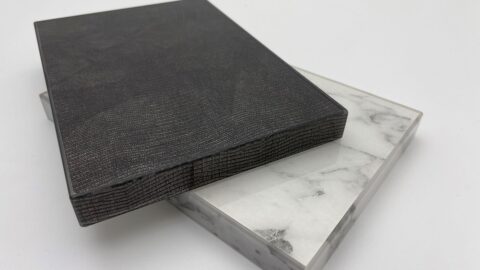

Product: SL RAW Jet Stream matt AR

It’s no secret that white and cream coloured fronts dominate the market – but does it always have to be a painted smooth surface? Consumers are demanding more and more and have less and less interest in mass-produced goods.

But what is required? Starting with a wider selection of designs and colours to unusual textures that don’t only have a visual effect, but can actually be felt and thus appeal to several senses.

SIBU DESIGN: Partner for the furniture and furniture supply industry

Stand out from the crowd

Our comprehensive range of furniture panels offers a wide selection of different decors and creates a strong differentiation from standard lacquered surfaces. Whether marble decors in high-gloss or matt, structured design panels with a special appealing feel, or attractive leather looks – the decorative surfaces turn the pieces of furniture into design objects.

PVA / PUR pressing

Most of the design panels are suitable for pressing with white or PUR glue. If necessary, we increase the surface tension of the back of the decorative panel with a special pre-treatment. Our product range also includes suitable accessories such as balancing materials and ABS or PMMA edges that match the design of the sheet

Don’t be afraid of new materials

The backing material of our decorative panels mainly consists of polystyrene (HIPS). It is a specially manufactured synthetic material which is, compared to HPL, impact resistant and does not break or splinter. Processing is done with standard woodworking tools or machines.

8 reasons why SIBU DESIGN panels are perfect for furniture fronts

Durable & easy-care

Our range includes design panels with especially high abrasion resistance (AR) as well as scratch-resistant (AR+) decorative panels. Our products are additionally very low-maintenance and easy to clean.

Special formats

Our stock size is 2600 x 1000 mm. For furniture series we are able to produce special sizes. This reduces costs and material waste.

Blanks

On order, we can cut our design panels to your required size. In addition, we offer punching elements specially manfaactured for you.

Pre-treatment

In order to make the back of the decorative panels suitable for pressing, we offer a material pre-treatment to achieve an perfect surface tension of at least 42 dyn/cm.

Matching edges

For many of our designs we offer ABS or PMMA edges that match the design. However, all edges available on the market can be used.

Ecological

In general we are focused on having a resource-saving production, in which – whenever possible – recycled materials are used. Especially sustainable: Our certified product line NATURE-LINE.

Quality from Austria

Each design panel is produced with special care from our experienced employees and 100% in Austria. Our products go through strict checks to guarantee a constant quality.

Stock items

Our design panels are all in stock and can therefore be delivered quickly. For cuts and pre-treatments we also only need a few working days.

For the processing and product installation of SIBU DESIGN panels, only a few important aspects need to be considered. You can find all the information in our processing instructions.

Get more information on the following areas

Ordering pre-treated decor panels

In order to achieve a perfect surface tension of the back of the decorative sheet for pressing, the panels can be ordered pre-treated. When and how you can do the pre-treatment yourself, you will find out in this article.

Pressing with PVA glue or PUR adhesive

To produce a furniture front with a decorative panel with material thicknesses of 1-4 mm, the design sheet must be pressed. All the steps that you need to consider you learn in this article.